Remedy Asset Protection | Australia | Coating and Corrosion Consultant

Corrosion and Coatings

RemedyAP consultants and inspection teams have a wide range of industry experience providing a resource to communicate with site teams whilst also collaborating in technical aspects of quality control, corrosion assessment and coating chemistry.

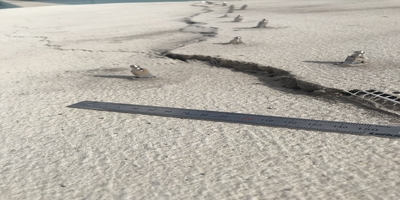

Protective coatings are designed to be long-lasting, and it is important to have coating inspection and inspection of concrete repair to ensure that this is the case. We support the corrosion control industry by offering Corrosion Inspection Services and provide thorough Corrosion Inspection and Corrosion Survey using non-destructive testing (NDT) on your project to ensure that your structure is safe from damage and deterioration.

Digitalization

RemedyAP can deliver digitalization to your organization by providing cloud-based asset management software. Whether we use your existing software systems or our Proprietary software, RemedyAP can upload condition assessments and coating surveys with scheduled maintenance and inspection duties for your team to action. It’s just a one click process to issue a work order for Staff or Contractors to get working on.

Architecturally Exposed Structural Steel (AESS) Coatings and Paint Inspector

Australian Standards reference various levels of steel finishing and protective coatings related to architecturally exposed structural steel (AESS). AESS is found in commercial and residential construction where many coating related issues lead to persistent corrosion problems. The RemedyAP inspection team have the necessary experience to review your project plans and ensure suitable corrosion protection is included in design and specification. Additionally, during construction our inspection service verifies the work is completed to meet requirements.

If you are already experiencing defective or aged coatings, RemedyAP can perform site assessment and provide the necessary technical advice to rectify and beautify your steel.

Concrete Assessment and Inspection

When assessing concrete structures, a field-based approach needs to be aligned with analytical processes to determine suitability of the existing concrete and to effectively treat the concrete structure to withstand further degradation for future use.

Concrete is a mixture of materials where the degradation mechanisms occur beyond the surface. Therefore, concrete assessment cannot be undertaken on the surface alone.

RemedyAP have procedures and techniques for collecting the right data to assist you in making the right repair and protection decisions.

With RemedyAP you will receive an inspection plan that can include; concrete scanning, compression testing, carbonation tests, defect mapping, surface tensile tests and many other methods.

Project appraisal and consultation

Condition assessment and repair recommendations

Specification and tender review

Independent quality inspections including non-destructive testing and project reporting

The Importance of Having Your Coating Inspected

As the owner of a project, it is important to have your coating inspected and analysed within NACE guidelines because if you leave your project open to corrosion it can be dangerous and also cost extra in repairs as the project coating deteriorates further.

As the owner of a project, it is important to have coating inspection and assessment of concrete repair strategies within NACE guidelines and using NDT because if you leave your project open to corrosion it can be dangerous and potentially cost extra in repairs as the project deteriorates further.

Contact us to organise an inspection

If you require the services of our accredited staff, please do not hesitate to contact us.

Call 1300 956 054 or email info@remedyap.com.au and we will reply to you as soon as possible.